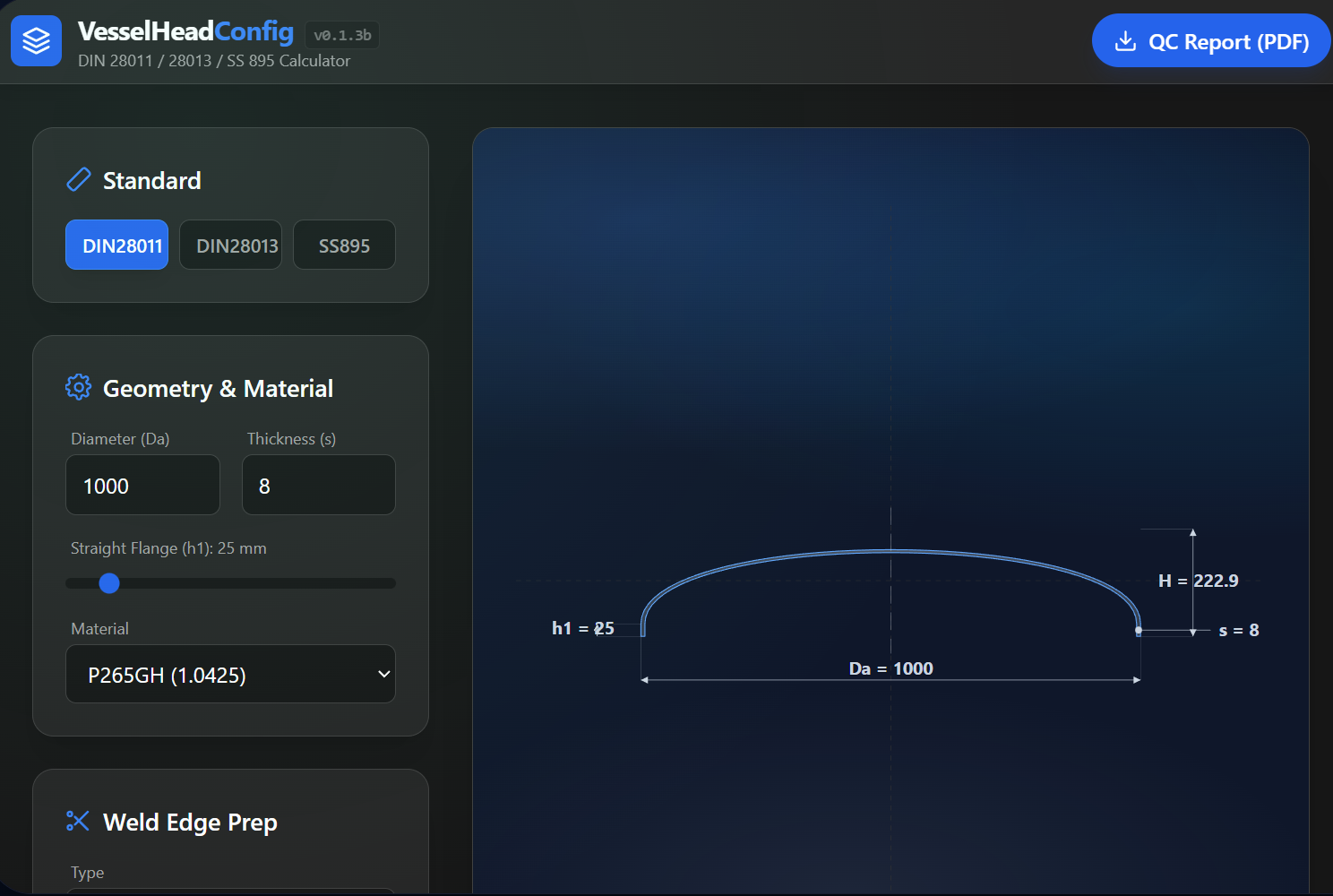

Dished End (Vessel Head) Calculator

Calculate geometry, blank diameter, and weight for Torispherical and Ellipsoidal heads (DIN 28011, DIN 28013, SS 895) with nozzle configuration and QC reports.

Open utility

What it does

Instant calculation of pressure vessel head geometry, weight, and volume. It generates a visual profile including nozzle positions and produces a printable "Manufacturing Report" with expected tolerances for quality control.

When to use it (and when not to)

Use it when:

- You need to estimate the weight and blank diameter for material ordering.

- You want to visualize nozzle positions relative to the head curvature.

- You need a quick QC sheet with standard tolerances (DIN 28005-1) for the shop floor.

Avoid it when:

- You are designing ASME 2:1 Ellipsoidal heads (unless the geometry matches the provided DIN/SS presets manually).

- You require ASME VIII Div 1 pressure ratings or stress analysis.

Inputs and outputs

Inputs

| Input | Description |

|---|---|

| Standard | Choose between DIN 28011, DIN 28013, or SS 895. |

| Geometry (Da, s, h1) | Outer diameter, wall thickness, and straight flange height. |

| Material | Select from common grades (P265GH, Stainless, Titanium) to determine density. |

| Edge Prep | Configurable V-Bevel angle and root face dimensions. |

| Nozzles | Add nozzles with specific DN sizes and offset positions. |

Outputs

| Output | Format | Notes |

|---|---|---|

| Geometry (H, h2, R, r) | Numeric | Full height, crown height, dish radius, and knuckle radius calculations. |

| Weight & Volume | Numeric | Estimated finished weight and internal volume. |

| Blank Diameter | Numeric | Theoretical flat plate diameter required for forming. |

| QC Report | PDF/Print | A formatted sheet with nominal values and blank fields for actual measurements. |

How to use

- Select the manufacturing standard (e.g., DIN 28011).

- Enter the Outer Diameter (Da), Thickness (s), and Straight Flange (h1).

- Configure the material and edge preparation (bevel angle/root face) if needed.

- (Optional) Add nozzles by specifying size (e.g., DN50) and offset from center.

- Click "QC Report (PDF)" to generate the printable manufacturing sheet.

Example dataset: Standard: DIN 28011, Da: 1000 mm, s: 8 mm, h1: 25 mm, Material: P265GH.

- Expected output: Total Height (H) calculated, weight estimation (~25kg), and a visual profile showing the dish radius and knuckle radius.

Accuracy and verification

- Geometry calculations follow the specific formulas for DIN 28011 (R=Da, r=0.1Da), DIN 28013, and SS 895.

- Tolerances in the report are derived from DIN 28005-1 (Formed Heads).

- Weight is calculated using standard densities (7.85 for Carbon Steel, 7.9 for Stainless).

FAQ

- Which standards are supported? DIN 28011 (Torispherical), DIN 28013 (Ellipsoidal), and SS 895.

- Does it calculate the blank diameter? Yes. It estimates blank diameter using standard factors (e.g., 1.09x or 1.14x Da) plus the straight flange.

- Can I configure weld preparation? Yes. You can select between a square cut (None) or a V-Bevel with configurable angle and root face.

- Is the QC report customizable? The QC report is auto-generated based on your inputs and includes DIN 28005-1 tolerances. It prints directly from the browser.

- Are my entries saved? No. Close the page to clear everything; it stays in your browser memory only.

Related tools

Changelog

- v0.1.3b: Added QC Report generation, nozzle configuration, and edge prep visualization.

- Initial release.

Feedback / bug report

- Open a GitHub issue

- Email or DM with the slug

pressure-vessel-dished-end-calcso we can reproduce the issue