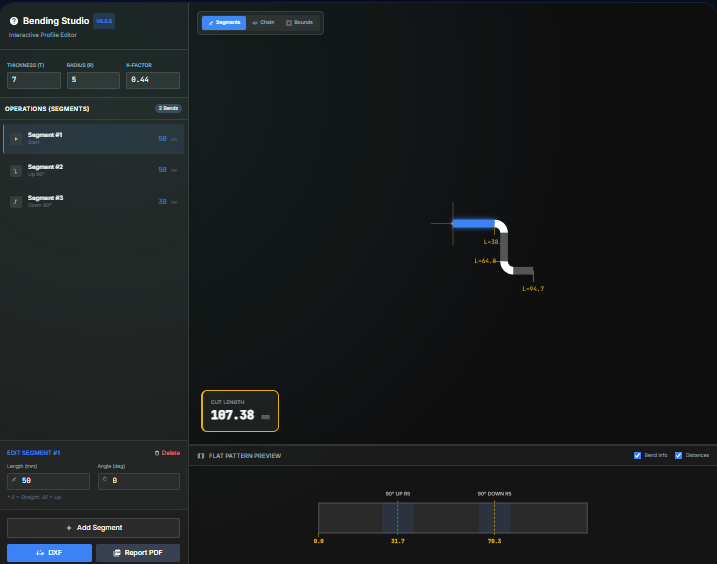

Metal Bending Prototype

Model flange lengths, neutral axis positions, and bend deductions for sheet metal jobs before committing tooling.

Open utility

What it does

Experiment with K-factors, bend deductions, and neutral axis positions before sending programs to the press brake. Enter thickness, radius, and angles to see total flat length and per-bend allowances that align with ISO 2768 or ANSI style tolerance blocks.

When to use it (and when not to)

Use it when:

- You are drafting or revising press brake programs and want to validate allowances before production.

- You want to tune K-factor or bend deductions to match a new material batch or brake tooling.

- You need a quick training aid for apprentices learning how flange lengths change with different radii.

Avoid it when:

- You are modeling stamped, roll-formed, or highly non-linear bends that need FEA or vendor data.

- You need automatic flat patterns for complex multi-bend parts; run this per bend and combine the results.

Inputs and outputs

Inputs

| Input | Description |

|---|---|

| Material thickness | Gauge or thickness of the sheet you are bending. |

| Inside bend radius | Radius at the neutral axis region; drives allowance values. |

| Bend angle | Formed angle after springback; enter consistent units. |

| Flange lengths | Leg lengths adjacent to the bend that roll into the flat length. |

| K-factor or bend deduction | Choose to drive calculations with K-factor or a known deduction. |

| Material or tooling notes | Optional notes to remind you of die width, grain direction, or brake setup. |

Outputs

| Output | Format | Notes |

|---|---|---|

| Total flat length | Numeric | Length to program or cut before forming. |

| Bend allowance / deduction | Numeric | Computed from thickness, radius, and angle for the specified K-factor. |

| Neutral axis location | Numeric | Position expressed as a factor of thickness for reference. |

| Summary card | On-screen | Values to copy into CAM notes or travelers. |

How to use

- Enter sheet thickness and inside bend radius.

- Set the bend angle and flange lengths that need flattening.

- Choose whether to drive the math from a K-factor or a bend deduction.

- Review the resulting flat length and allowance numbers.

- Copy the values into your CAM program or save a screenshot for the router.

Example dataset: Thickness: 3 mm, Inside radius: 4 mm, Bend angle: 90 deg, Flanges: 50 mm and 75 mm, K-factor: 0.38.

- Expected output: Shows flat length and bend allowance for the two-leg bend so you can program the brake or CAM flat pattern.

Accuracy and verification

- Assumes air bending with a single K-factor across the bend.

- Does not account for grain direction or tooling wear; verify with a bent coupon before a full run.

- Keep your input units consistent; the tool does not convert mixed values.

- Use press brake test pieces to refine K-factor for each material lot.

FAQ

- Does it support multiple bends? Use it per bend or per leg; combine the results for complex parts.

- Can I work in inch and metric? Yes. Enter values in the units you use; the math is unit-agnostic.

- How do I export the numbers? Copy them directly from the summary or take a quick screenshot.

- Does it run offline? Yes. Everything runs locally in your browser.

- What if my brake uses bend deduction tables? Select bend deduction mode and plug in the table value to see the resulting flat length.

Related tools

Changelog

- Initial documentation.

Feedback / bug report

- Open a GitHub issue

- Email or DM with the slug

metal-bendingso we can reproduce the issue